Mechatronics Keychain

What?

A keychain project undertaken by all University of Waterloo Mechanical and Mechatronics Engineering students

requiring the assembly of a 7-component keychain from physical materials to a fully developed CAD model and mechanical drawing.

Building the Keychain

Building the Keychain

Building the physical keychain was done using machinery such as a milling machine, lathe, drill bit, tap and dye, deburring tools and belt grinders at the University of Waterloo Student Machine shop. In order to enter

the student machine shop, safety training including WHMIS 2015 and machine training was done in preparation.

Modelling the Keychain

Modelling the Keychain

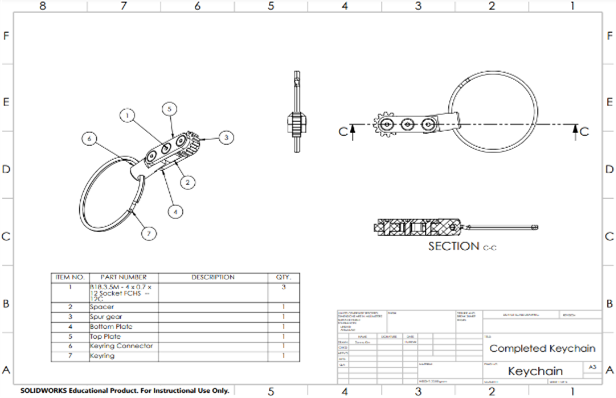

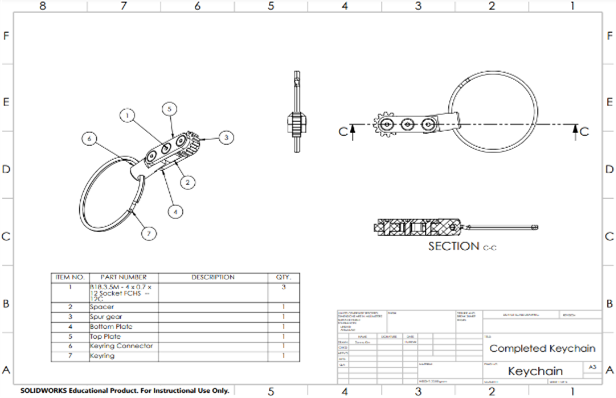

The CAD model of the keychain was developed in SOLIDWORKS, using a vernier caliper and micrometer to ensure accurate measurements were taken from the physical keychain. Each of the 7 components was designed in SOLIDWORKS

and put together in an assembly that mimics real life movement of the keychain.

Mechanical Drawing

Mechanical Drawing

Mechanical assembly drawing was made using SOLIDWORKS, including a Bill of Materials (BOM), material properties, GD&T annotation, and section views of all machined components.